Understanding Thermal Oxidation: An Effective Solution for Industrial Odor Control

Thermal oxidation is a widely used method for industrial odor control. It effectively removes odorous compounds by breaking them down at high temperatures. Many industries rely on this technology to maintain clean air and comply with environmental regulations. Facilities such as food processing plants, petrochemical refineries, and wastewater treatment sites often deal with persistent odor challenges.

Thermal oxidation is a widely used method for industrial odor control. It effectively removes odorous compounds by breaking them down at high temperatures. Many industries rely on this technology to maintain clean air and comply with environmental regulations. Facilities such as food processing plants, petrochemical refineries, and wastewater treatment sites often deal with persistent odor challenges.

At Webster Environmental Associates (WEA), we create customized thermal oxidation systems. Our team evaluates each facility’s needs and recommends systems that deliver reliable odor control. With our experience in designing and implementing odor control solutions, we help businesses achieve better air quality and regulatory compliance.

How Thermal Oxidation Works

Thermal oxidation breaks down odorous compounds by exposing them to high temperatures in the presence of oxygen. This process converts harmful gases into carbon dioxide and water vapor, which are much safer for the environment. The effectiveness of thermal oxidation depends on maintaining the right temperature, retention time, and oxygen levels.

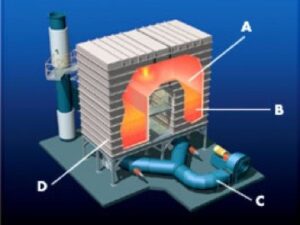

A thermal oxidizer consists of several key components. The combustion chamber is where the odors are treated by applying intense heat. Burners supply the necessary heat to initiate the oxidation process. Airflow controls make sure that odorous gases are evenly distributed within the chamber for complete treatment. A heat recovery system may also be included to improve energy efficiency by capturing and reusing excess heat.

Oxygen and heat play critical roles in neutralizing odors. Sufficient oxygen ensures that all odorous compounds break down completely, while maintaining the right temperature allows for efficient treatment. WEA carefully designs each system to achieve the right balance for effective odor control.

Applications of Thermal Oxidation Across Industries

Thermal oxidation is used in a variety of industries where odor control is a priority. Food processing facilities generate strong odors from organic waste, cooking operations, and storage areas. Thermal oxidizers effectively break down these emissions and improve air quality in and around the facility.

Petrochemical plants produce volatile organic compounds (VOCs) that contribute to both odors and air pollution. Thermal oxidation helps manage these emissions by breaking down harmful compounds before they are released into the air. This process not only improves working conditions but also helps facilities meet strict environmental standards.

Wastewater treatment facilities also face significant odor challenges. Hydrogen sulfide and other odorous gases produced during wastewater processing can create unpleasant conditions for both workers and nearby communities. Thermal oxidation provides an efficient solution by eliminating these gases before they can escape into the environment.

Advantages of Using Thermal Oxidation

Thermal oxidation offers several advantages for industrial odor control. One of the biggest benefits is its high efficiency in removing odors and harmful compounds. The process ensures that emissions are thoroughly treated and leave no unpleasant smells behind.

Another advantage is its minimal environmental impact. When properly designed and maintained, thermal oxidizers produce safe byproducts such as carbon dioxide and water vapor. Facilities using this technology can reduce their overall emissions and contribute to a cleaner environment.

Compliance with air quality regulations is another key benefit. Many industries must follow strict guidelines to control emissions and protect public health. Thermal oxidation helps businesses meet these requirements by providing a reliable and effective odor treatment method. At WEA, we work with clients to make sure their systems meet all applicable regulations and perform optimally.

Why Choose WEA for Thermal Oxidation Solutions

Choosing the right partner for odor control is important. WEA has extensive experience in designing and implementing thermal oxidation systems for various industries. Our team understands the challenges businesses face and provides recommendations to address specific odor control needs.

Choosing the right partner for odor control is important. WEA has extensive experience in designing and implementing thermal oxidation systems for various industries. Our team understands the challenges businesses face and provides recommendations to address specific odor control needs.

We take an unbiased approach when recommending odor control technologies. WEA remains independent from equipment manufacturers, which allows us to choose the best technology for each facility without bias. Our focus is on finding cost-effective and efficient solutions that work for our clients.

Ongoing support is another reason to work with WEA. We provide system optimization, maintenance support, and performance monitoring to ensure long-term success. Our team helps clients keep their systems running efficiently and in compliance with regulations.

Find Out if Thermal Oxidation is Right for Your Facility

Thermal oxidation is a reliable and effective method for controlling odors in industrial facilities. It helps businesses maintain clean air, comply with regulations, and improve overall operations. Whether in food processing, petrochemical, or wastewater treatment industries, this technology offers an efficient way to address odor challenges.

WEA provides expert guidance and customized solutions to help facilities achieve peak performance. Our experience and commitment to quality make us a trusted partner for industrial odor control. Contact us today to learn more about how our thermal oxidation services can benefit your facility.